Discover Vision Engineering

Respected by scientists, engineers and technicians across the globe, Vision Engineering Ltd is a true British success story. Founded in 1958, we are the world’s leading ergonomic microscopy company, designing and manufacturing high-quality microscopes, digital instruments, and metrology systems.

Today, we export over 90% of our products around the world. Our success comes from a culture of innovation, quality and ergonomic design.

Creative innovation

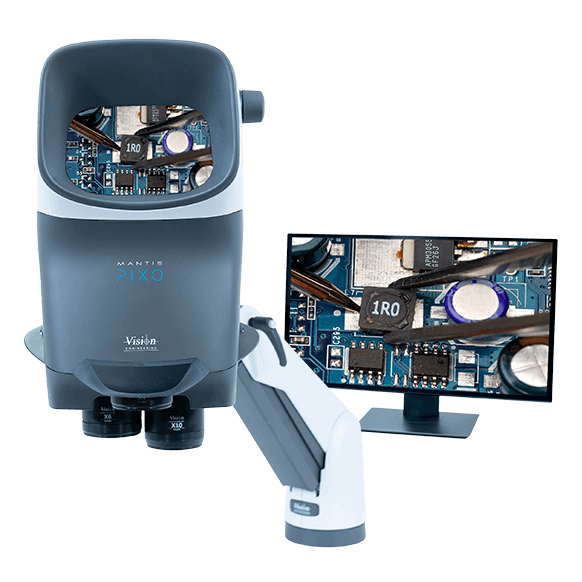

Our patented eyepiece-less optical technologies are changing how people work for the better. We have replaced conventional binocular microscope eyepieces with our industry-leading ergonomic design.

An unswerving commitment to quality

From supply chain to product manufacture and after-sales care, our procedures are continually evaluated, enhanced and documented.

Quality is our mission; it is our passion. That’s why everyone on the team is empowered and motivated to support our aim of excellence in all we do.

Advanced ergonomics for operator comfort

If you’re using a piece of equipment for multiple hours, your comfort and ease of use must be a priority. This principle is built into the design of every microscope and measuring system we make.

Good ergonomic qualities are essential. We ensure the product is comfortable and easy to use to reduce operator discomfort and fatigue. Our patented microscope viewing heads let operators adopt a natural, stress-free posture, promoting efficiency and enhancing productivity.

Operator comfort for greater productivity

With our eyepiece-less optical technology, we have removed the need for operators to align their eyes with traditional eyepieces. Muscles stay relaxed, eliminating the discomfort associated with prolonged conventional microscope sessions.

Plus, there is no exposure to intense light; a leading cause of eye fatigue. Instead, users sit comfortably, allowing ambient light into their eyes. And if operators wear glasses, they don’t need to take them off.

Easy hand-eye-co-ordination

Hand-eye coordination is essential for re-work, repair, dissection and other manipulation tasks. With conventional binocular microscopes, that’s a challenge. But with our award-winning range of digital 3D stereo microscopes, it’s easy.

Global presence. Local service

You’ll find our people in offices across North America, Central America, UK, Europe and Asia, working directly to support you and through a fully trained global distribution network. Together, we’re bringing the best British and American inspection and measurement products to some of the world’s best-known brands.

Turning your ideas into reality

Vision Engineering Manufacturing Services offers comprehensive contract manufacturing, design and commercialisation packages. Access the latest technology supported by our team of experienced designers and engineers.

Whether it’s design, prototyping, manufacture, assembly, logistics or all of the above, our team are here to help. We can share over six decades of experience in the design, development and exploitation of hi-tech products.

One team for everything

From bespoke prototypes to mass production projects and all aspects of purchasing, shipping and marketing, a dedicated project management team is assigned to coordinate all your requirements.

State-of-the-art machine shop

You can trust in our technology, capacity and capabilities. Vision Engineering continues investing in advanced manufacturing facilities with modern milling, turning and finishing technology, paint and assembly shops. We ensure full traceability: where materials are sourced, used, and what processes they’ve gone through.

Accreditation

Our investments in quality, innovation and manufacturing continue to this day. It’s something we’re proud of. You can see it in our numerous industry awards, membership in every relevant trade association and our accreditations.