Medical precision and consistency

When the medical devices you are inspecting have been manufactured to the finest tolerances, even the slightest knock or pressure applied in the wrong place can turn an exemplar into a reject in a moment. Non-contact measuring solutions from Vision Engineering, such as the TVM family of digital measuring microscopes, reduce the risk of accidental damage and inadvertent contamination, whether the subject has been made from metal, plastic, rubber, or a combination.

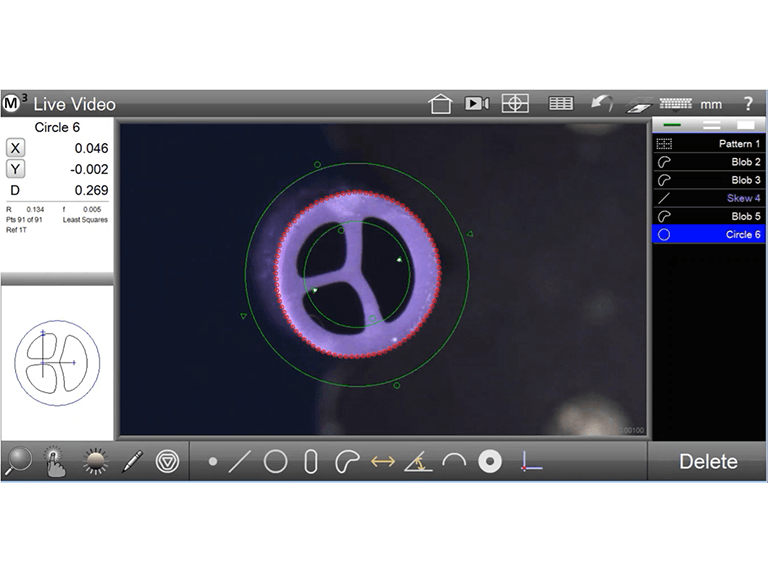

Irregular shapes

The irregularly shaped subjects of medical products can be impossible to measure with standard measuring equipment. Multi lumen tubing for example, can require a range of measurements such as the outer diameter, several internal diameters and wall thicknesses which have to be measured in relation to one another. Vision Engineering’s non-contact measurement systems, such as TVM, with large fields of view, get the job done quickly and with accurate, repeatable measurements in any orientation.

Compatible with protective equipment

Vision Engineering’s Mantis and Lynx EVO stereo microscope solutions make it easy to inspect medical stents, guide wires and other devices intended for insertion into the human body, for burrs, breaks and islands. What’s more, inspection is just as easy with no optical compromise – when you’re wearing a full set of safety glasses, masks, gloves and gowns.

Precision inspection for precision engineering

When even a small defect that’s invisible to the naked eye could cause serious complications for the patient, you can rely on Vision Engineering. Our ergonomic microscopes and measuring systems improve every stage of the manufacturing process, from the early design of new medical equipment right through to prototyping, full production, inspection and quality control. Use it for checking catheters, stents, implants, pace makes, insulin pumps, guide wires, replacement heart valves, angioplasty balloons and much more.

Unrivalled consistency

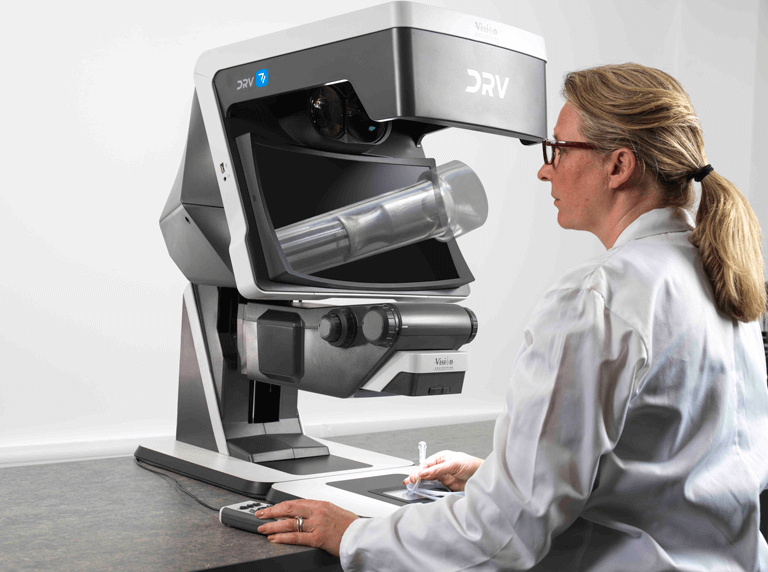

Inspections of devices made in one location should unarguably be consistent with inspections of the same equipment on another day, and in another place. And that means the measuring and inspection equipment in every location should be configured with identical settings. Vision Engineering’s EVO Cam II and DRV-Z1 have the ability to share settings between multiple units on multiple sites for reliable, documented consistency.

Integrated inspection

Choose one of our Mantis 3D stereo microscopes when you want to inspect bone screws and bone plates as soon as they have been machined, immediately revealing any scratches or burrs. The magnification range, exceptional operator comfort and superb 3D imaging make Mantis the preferred solution for long inspection sessions. Mantis is also ideal for performing batch checks in the production line

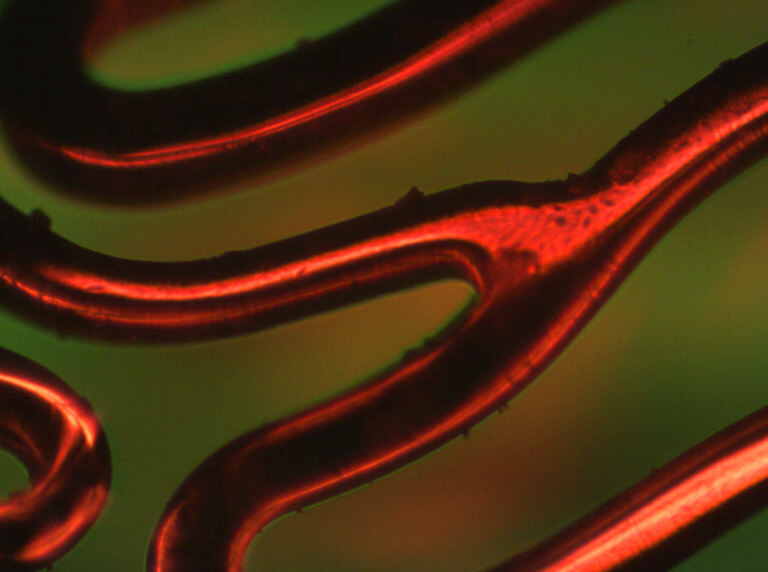

Catheter inspection

Use EVO Cam II digital microscope with a polarised light to look for hidden imperfections in catheters and other tubing to reveal imperfections that wouldn’t be seen under normal light.

SUCCESS STORIES

Mantis allows our inspectors to maximise the use of their hands when turning and rotating the component. With other magnification systems, we have found we have to spend needless time aligning the binocular head to see the product clearly. However, with Mantis and its viewing head, we can see the component instantaneously.

Now we have an accurate way of measuring the face plates, we are able to check the supplies match the drawings. Without it we would just have to accept that the suppliers have manufactured the substrates within the tolerance given to them.

For many years we used a profile projector to assess the measurement of our components but we felt the need for a more precise measurement instrument, with a much wider and more modern capability. It seemed to us that the solution offered by Vision’s Hawk System could satisfy all of our requirements. The Hawk offered good benefits to not only the development in the initial stages but also to the pre-production stage as well.

Mantis

Eyepiece-less 3D stereo microscope offering exceptional operator comfort and superb 3D imaging.

TVM

TVM is ideal for taking 2D measurements of multiple subjects.