Our recent surveys have shown that 55% of all respondents are still having some sort of PCB solderability issues.

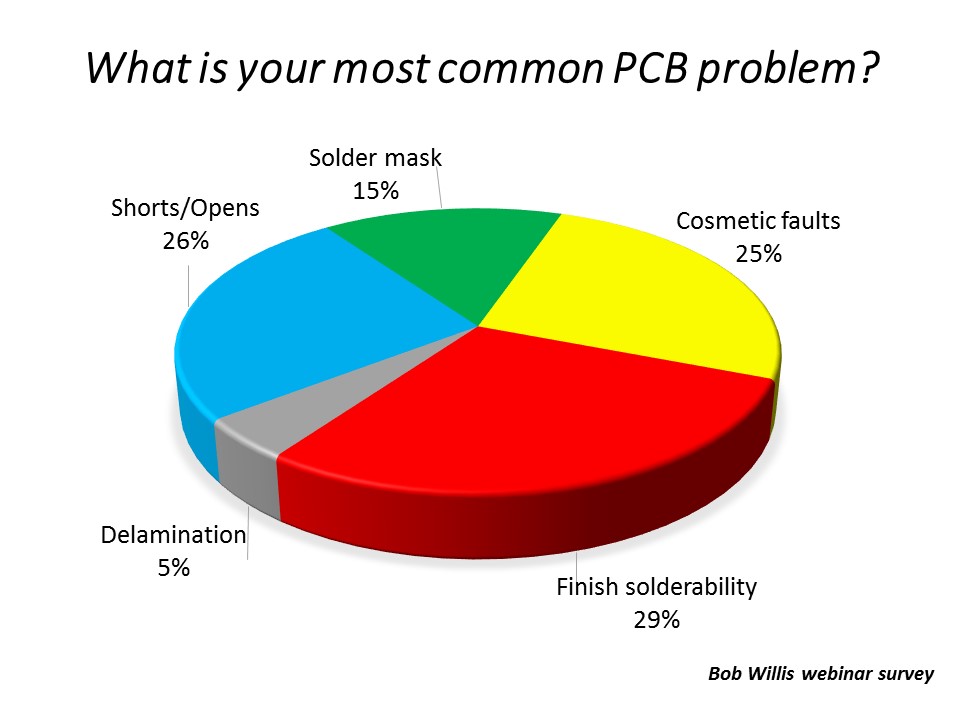

The “What is the most common PCB problem?” survey showed that 29% of all respondents had problems with solderability finishes and 26% were having shorts and opens related issues. The above findings could be possibly linked to the Class 1 PCBs – the most common type on the market where the quality of solder joints or component positions is not a top priority and expected not to last very long, but this would need further research.

Only a small part of the survey participants (5%) indicated delamination as a common issue. This could mean that the structure of the PCB and the quality of adhesion on multilayer PCBs have vastly improved for the past few years. Cosmetic faults scored a substantial 25% of all issues, but this type of defect has only visual impact on the PCB and doesn’t affect its functionality or connectivity.

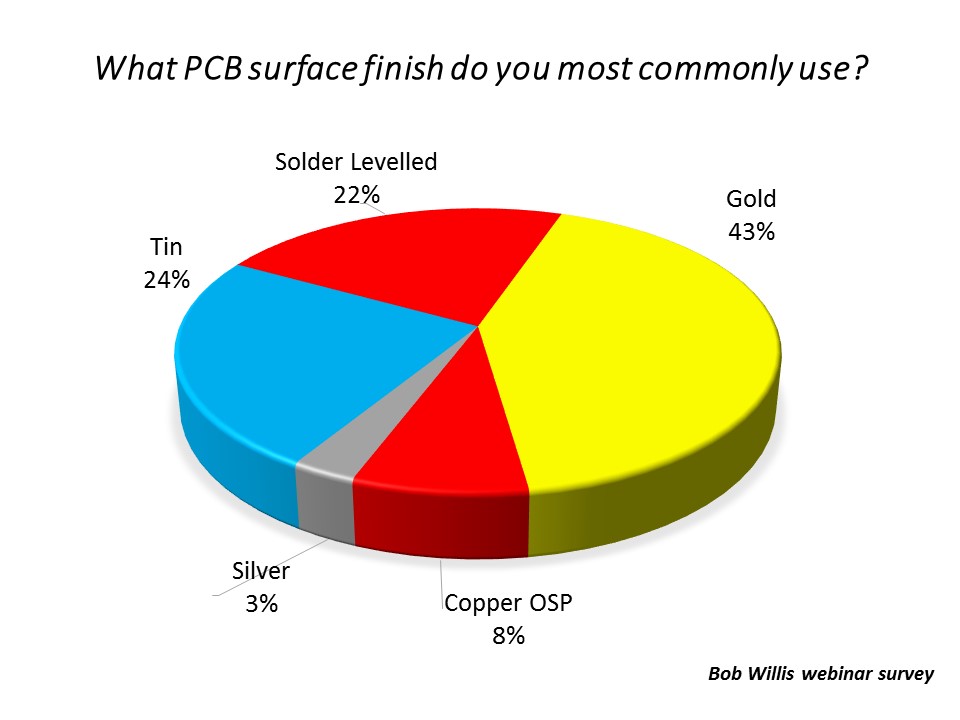

The “What PCB surface finish do you most commonly use?” poll revealed that almost half (43%) of the Printed Circuit Board had gold (hard, soft and flash type) finish now, one quarter (24%) had tin finish followed closely by solder levelled types (22%). Silver and copper finishes corresponded to only 11% of all manufactured PCBs.

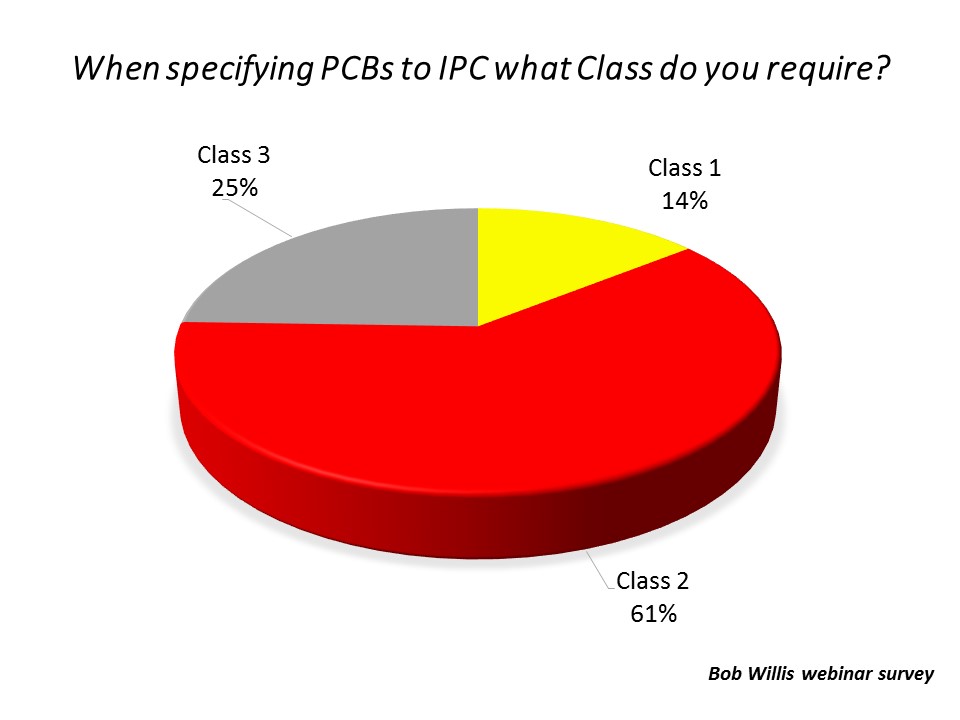

The “When specifying PCBs to IPC what Class do you require?” survey showed that the most common type of PCB is Class 2 (66%), typically requested for non-critical electronic assemblies where longer term reliability is desirable, rather than essential. According to the same survey, one quarter (25%) of attendees had manufacturing requirements for Class 3 PCB types – the highest IPC standard, and aim at more critical PCB assemblies, and Class 1 only related to 14% of all PCBs.