In this article we look at the advantages of investing in eyepiece-less stereo microscope systems and the impact they can have on health and productivity.

Understanding the exit pupil: why it matters

Understanding the exit pupil is key to understanding the benefits of an eyepiece-less microscope. The exit pupil is the diameter of light that exits the microscope’s optics, which is typically small in traditional binocular microscopes. Practically, this means you need to stay close to the eyepieces to maintain a clear image.

Eyepiece-less microscopes, however, offer a much larger exit pupil – up to 35mm – which immediately offers flexibility in positioning and a more comfortable viewing experience.

With this fundamental difference in mind, let us now explore 7 main advantages of switching to an eyepiece-less stereo microscope system.

1. Enjoy greater freedom of head movement

Avoid a fixed head position

Traditional stereo microscopes have a narrow exit pupil, which requires precise alignment with your eyes. This means that your head movement will be limited because even a small shift can make the image unclear.

Eyepiece-less microscopes, however, feature an expanded exit pupil, allowing you to move freely without losing focus. This freedom reduces strain, especially during long sessions, and prevents discomfort.

2. Work more comfortably

Improve microscope ergonomics for better productivity

Microscopy can strain the skeletal system. Holding an unnatural position for long periods can lead to discomfort and cause errors. Traditional microscopes force you to stay in one position, which can cause neck and back problems over time.

Research shows that over 90% of conventional microscope users have suffered neck strain due to prolonged, awkward positions1. In contrast, eyepiece-less microscopes promote a more natural, relaxed posture, reducing the risk of fatigue and long-term injury.

3. Manipulate objects without losing focus

Improve hand-eye coordination and object handling

Traditional microscopes can make it difficult to manipulate objects with precision. The limited field of view and fixed position can restrict your movement and peripheral vision making it harder to handle the object that you are handling.

Eyepiece-less microscopes let you to sit further back from the system, giving you better peripheral vision and more flexibility in handling tools and objects. This improves safety and efficiency.

4. Reduce eye strain and headaches

Eliminate eyestrain

94% of microscope users reported visual problems or a combination, of eye discomfort including headaches and dry eyes. Understanding the main causes of this discomfort can help highlight why eyepiece-less microscopes offer a more comfortable alternative.

| Traditional Microscope | Eyepiece-less Microscope |

| Narrow light beams enter the eyes, forcing the pupils to constrict. This constant dilation and constriction can lead to eyestrain and headaches. | The light beam from an eyepiece-less microscope is larger, allowing you to sit back. This results in a more natural pupil dilation with less variation in constriction and dilation. |

| You need to be positioned close to the eyepieces to use, restricting the amount of ambient light that can reach the eyes. | You can maintain a greater distance from the microscope, allowing more ambient light into the eyes, creating a more comfortable viewing experience for longer sessions. |

| If you shift focus or look away from the eyepieces, your eyes need to refocus, leading to repetitive iris contraction and expansion. This causes strain over time. | The focal distance in eyepiece-less microscopes mimics direct viewing, reducing the need for refocusing. This helps alleviate strain caused by switching between direct and magnified views. |

5. Wear glasses/safety goggles

No more restricted views

Glasses wearers often struggle with traditional eyepieces because the exit pupil size doesn’t accommodate eyewear. The exit pupil in conventional microscopes typically ranges from 3mm to 5mm in diameter, about the same size as the pupil in daylight. For clear viewing, the exit pupil must completely cover the user’s pupil and stay aligned without difficulty.

However, when glasses wearers cannot get close enough to the eyepiece, the image may be in focus, but the field of view becomes restricted. It’s also harder to keep the exit pupil aligned with the eye’s pupil, and a slight shift in position can cause shadowing in the view.

6. Reduce the risk of cross contamination

Enhance workplace health and safety

There are significant health and safety benefits associated with eyepiece-less microscopes compared with binocular microscopes.

As well as their ergonomic advantages, eyepiece-less microscopes reduce direct contact with the instrument, cutting the risk of cross-contamination, especially in shared environments. Without the need for eyepiece adjustments, you can maintain a more hygienic workspace.

This is ideal for industries like electronics or life sciences, where contamination could affect product quality. The longer eye-relief distance also makes eyepiece-less stereo microscopes suited for use in laminar flow cabinets, helping to prevent contamination when working with sensitive materials.

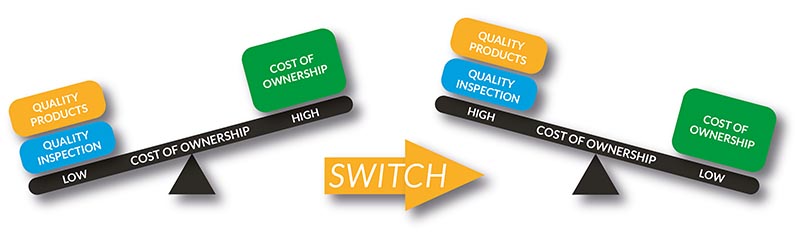

7. A cost effective solution

Consider the long-term savings

While price is often a deciding factor, the true cost of ownership of your stereo microscope needs to be considered. Poor-quality microscopes will lead to increased waste, rework, and warranty claims, ultimately costing more in the long run. Studies indicate that poor inspection quality can account for up to 20% of production costs in manufacturing3, depending on the industry and quality management practices. So without addressing these quality standards, manufacturers risk damaging their reputation.

Beyond quality, production delays caused by employee health issues, such as eye strain, headaches, or fatigue from long periods of microscope use, can result in missed deadlines and lost revenue. Eyepiece-less microscopes help mitigate these issues, offering enhanced user comfort, reducing eye strain, and increasing overall productivity.

Summary

By choosing an eyepiece-less microscope, you and your business can reduce downtime, avoid costly health-related absences, and increase efficiency. Though the initial cost may be higher, the long-term benefits – improved comfort, reduced rework, and higher productivity – make it a smarter investment.

Careful consideration of investment is key, but it is also important to plan ahead and consider how your business may evolve. Don’t forget to factor in the hidden costs, like potential damage to your reputation due to poor-quality results. The true cost of a microscope isn’t just the price tag – it is about protecting both your employees and your brand.

To find out more about the range of eyepiece-less microscopes available from Vision Engineering, visit:

https://www.visioneng.com/products/eyepiece-less-stereo-microscopes/

Endnotes:

1. Khalid L, Shah SN, Salik S, Rana AA, Dastgir H, Tariq R. Prevalence of Neck Pain and Awareness of Ergonomics among Microscope Users. The Healer Journal. 2023;3(1). Published December 1, 2023.

2. Jain, G., & Shetty, P. (2014). Occupational concerns associated with regular use of microscope. International Journal of Occupational Medicine and Environmental Health, 27(4), 591–598

3. Lin B, Boyer A. Defect Waste in Lean: How to Reduce Quality Issues. Lean Outside the Box. 2025;1(1). Published March 21, 2025