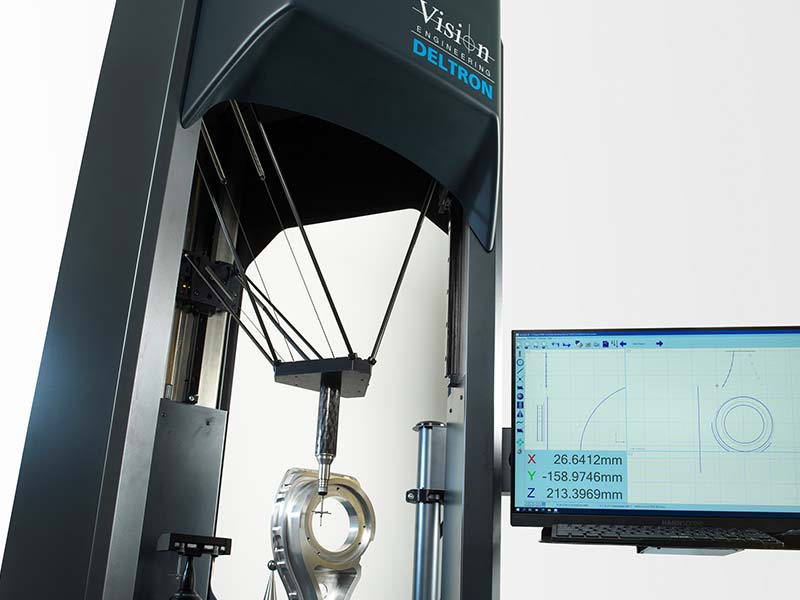

Vision Engineering has moved shop floor CMM design forward with the new DELTRON, featuring a delta mechanism, and delivering a unique combination of compact dimensions, accurate measurement and ease of use.

Designed for robustness, reliability and ease of use, the new Co-ordinate Measurement Machine (CMM), DELTRON is a robust shop floor hardened non-Cartesian CMM with an innovative delta robotic mechanism, supporting a high level of measurement accuracy. DELTRON will run 24/7, making it ideal whether it is positioned next to a machine tool, in a manufacturing cell, or used in a dedicated inspection area.

DELTRON features fully sealed recirculating bearings, delivering four key benefits – no dirt ingress, no gearbox, no compressed air requirement and smooth, fast operation. Together these deliver exceptional accuracy, simplicity and reliability. Scale resolution of 0.1 μm and volumetric accuracy of (2.6+0.4L/100) μm combined with weight-saving carbon fibre arms deliver a high level of confidence in the measurement output – speed and accuracy you can rely on.

Güven Türemen, Vision Engineering’s Group Commercial Metrology Manager said:

“We are delighted in adding Deltron to our growing metrology product range, We know how important it is to have a robust and easy to use CMM in the heart of our machine shop to ensure consistent quality and compliance. Our emphasis has always been on ergonomics and ease of use in a production environment.”