Optimising the manufacture of jewellery-grade lab-grown diamonds

Natural diamonds are expensive and as demand continues to rise there is an increase in interest for high-quality lab-grown diamond manufacturing.

Under natural conditions, diamonds form over billions of years whilst synthetic diamonds can be grown in only a number of weeks. Lab-grown diamonds are synthesised by artificially simulating the crystallisation and growth conditions of natural diamonds. Unlike simulated diamonds, such as cubic zirconia, lab-grown diamonds share all the physical, chemical and optical compositional properties of natural diamonds.

Traditionally grown for industrial use in areas such as machining, electronics and semiconductor technology, advancements in equipment and methodology have progressed lab-grown diamond manufacturing, allowing better inspection and repeatability for jewellery grade synthetic diamonds.

Diamond Manufacturing Processes

There are two main processes used to create lab grown diamonds:

High Pressure, High Temperature (HPHT)

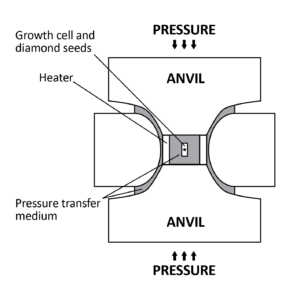

The HPHT synthesis method combines a diamond seed, a metal mixture as a catalyst and a carbon source under extreme pressure and heat to replicate the deep earth conditions where diamonds naturally form.

Chemical Vapour Deposition (CVD)

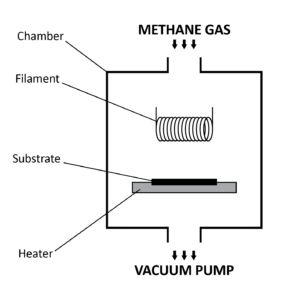

Unlike HPHT, the CVD synthesis method synthesises diamonds in a vacuum. The chamber is flooded with carbon rich methane gas and heated to promote ionisation. Carbon atoms are then deposited on the diamond seeds, growing until a fully formed diamond remains.

In the development and production process of lab-grown diamonds, optical inspection is extremely important for observation and recording of internal and external diamond sample characteristics. These characteristics can be imperceptible to the untrained eye and yet have a marked effect of the value and use of the final diamond.

Diamond Inclusions

A pure, structurally perfect diamond is extremely rare, even in natural diamonds.

Due to the catalysts used in HPHT Diamonds, metal inclusions can occur. Whilst CVD diamond inclusions are less common due to the growth method, they may have pinpoint inclusions or an unusual strain pattern that can identify it as lab-grown. Often inclusions relate to the speed of growth.

Whilst naturally an electrical insulator, the addition of boron in a diamond transforms it into an electrical conductor for use in electronics. Alternatively, including nitrogen in the growth process may result in a yellow coloured diamond with an unusual lattice structure that is harder than a natural diamond.

Industrial applications may benefit from these inclusions within the diamond, but for use as a gemstone, inclusions and structural irregularities may result in imperfections.

The clarity of jewellery grade diamonds is measured on a scale from Flawless (no visible blemishes under 10x magnification) to Included (obvious inclusions under 10x magnification, with an effect on transparency and brilliance). Colour is similarly graded. Faint to lightly tinted diamonds hold significantly less value than near colourless diamonds.

Finding the right tool:

With such a thorough and regulated grading system, it’s essential that the process for growing synthetic diamonds is highly repeatable and optimised to maximise desirable features. In order to ensure this, an optical or digital inspection system can be used to check for tints, spotty inclusions and undesirable strain patterns in lab-grown diamonds.

Our customers use:

3D depth perception and bright, high resolution imagery make the Lynx EVO an ideal solution for accurately viewing even the smallest of diamond inclusions.

‘Dynamic view optics’ enable operators to look ‘around’ the diamond, offering a far greater level of structural analysis and cut grading. Unique ergonomic design allows users to both directly view the subject and also access their peripheral vision for improved hand-eye coordination when manipulating samples.

Quickly and accurately observe colour and clarity with the EVO Cam II. High magnification and a range of digital pre-sets allow for consistent inspection every time.